Handheld Bio-Printer Prototype

Abstract

This research project developed a handheld bio-printer prototype capable of printing live cells using various bio-inks. The device can extrude up to four different bio-inks in both helical and standard structures, representing a significant advancement in tissue engineering and regenerative medicine by enabling precise in-situ bioprinting applications.

Methodology

The development process incorporated advanced engineering and biological techniques:

Design & Prototyping

- Conceptual design and requirements analysis for medical applications

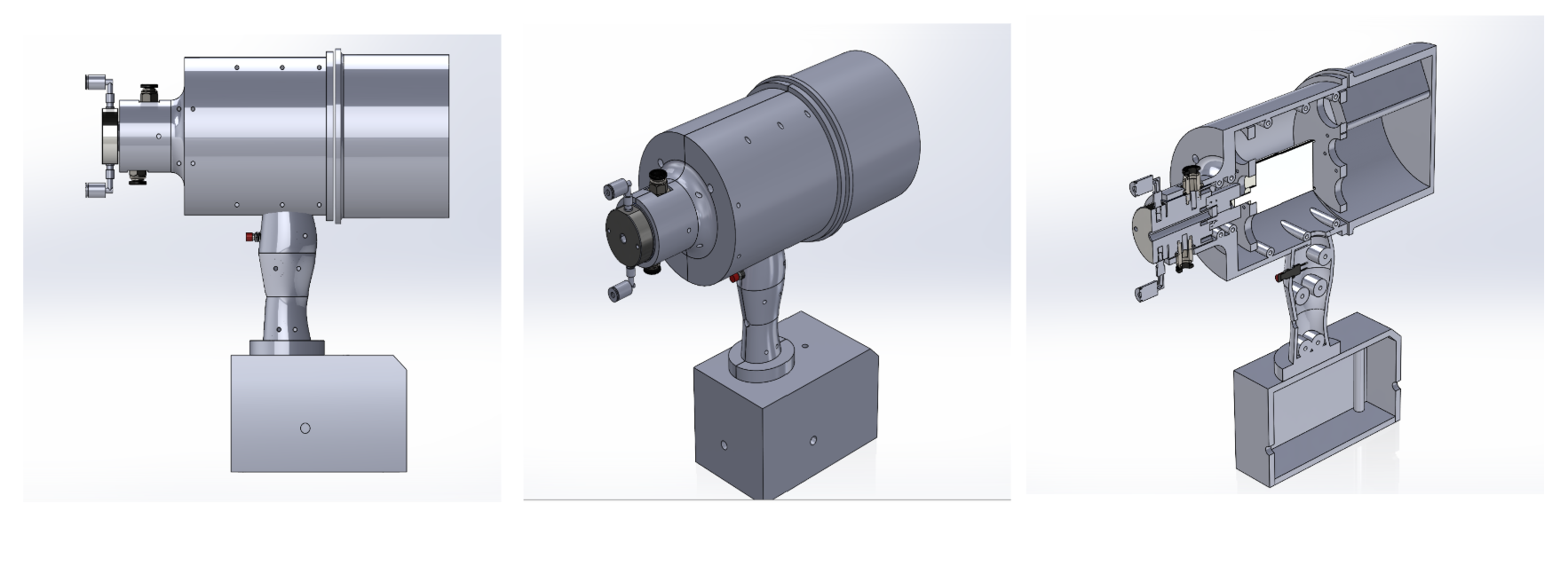

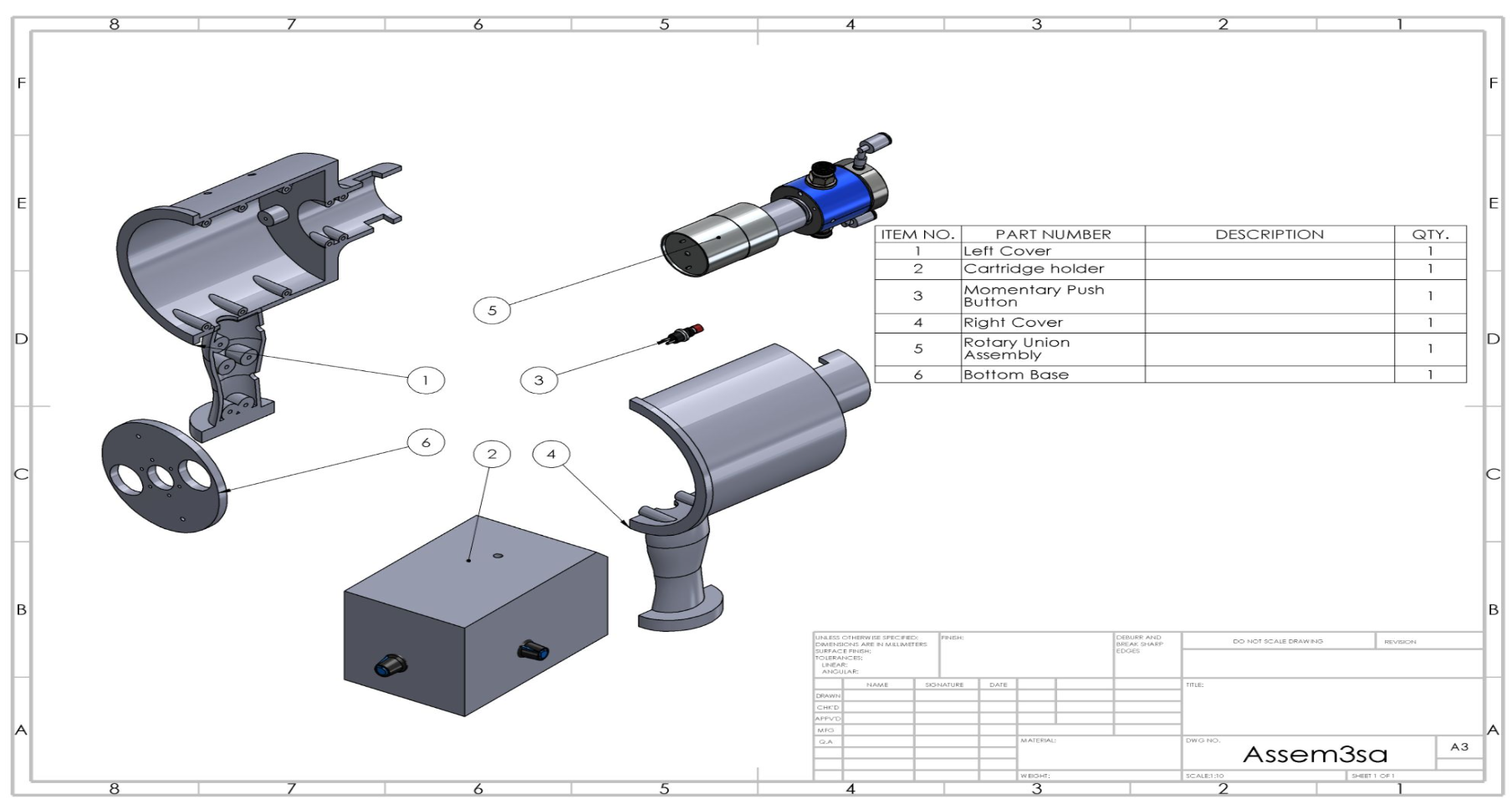

- CAD modeling of components using SolidWorks

- 3D printing of prototype parts using biocompatible materials

Bio-Integration

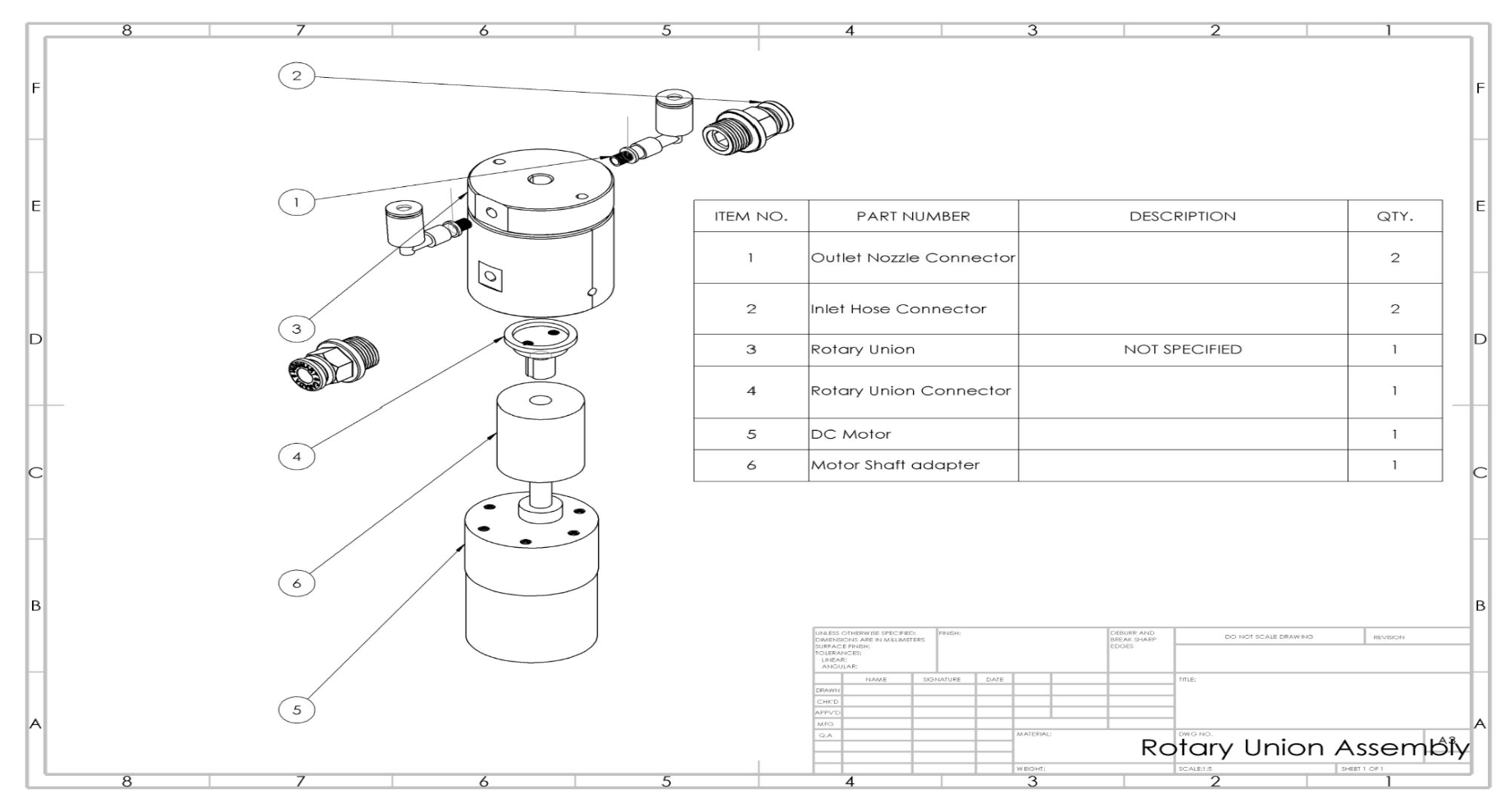

- Development of multi-nozzle extrusion system

- Integration of precision dispensing mechanisms

- Testing with various bio-ink formulations

The compact, user-friendly form factor enables precise in-situ bioprinting applications

Advanced mechanism allowing simultaneous printing with up to four different bio-inks

Precision-engineered components working in harmony for reliable cell deposition

Key Innovations

Multi-Bio-Ink Capability

Simultaneous printing with up to four different bio-inks enables complex tissue structure creation

Helical Structures

Unique capability to print helical patterns, mimicking natural tissue architectures

Ergonomic Design

Handheld form factor allows for direct in-situ printing during surgical procedures

Impact and Future Directions

This prototype represents a significant advancement in bioprinting technology with wide-ranging applications:

Surgical Applications

Potential for direct tissue repair during operations

Research Advancements

Enables new tissue engineering research methodologies

Drug Testing

Facilitates creation of complex tissue models for pharmaceutical testing

Future Enhancements

- Temperature-controlled bio-ink reservoirs for sensitive cell types

- Integrated UV crosslinking system for instant hydrogel solidification

- AI-assisted printing path optimization

- Wireless control and monitoring interface

Conclusion

The handheld bio-printer prototype represents a transformative approach to bioprinting, combining precision engineering with biological innovation. Its ability to create complex, multi-material tissue structures in situ opens new possibilities for regenerative medicine, surgical applications, and pharmaceutical research. Future development will focus on enhancing its capabilities while maintaining the portable, user-friendly design that makes it uniquely valuable in both clinical and research settings.