Autonomous Logistics Robot - IEEE Competition

🎯 Competition Objective

Develop an autonomous mobile manipulator system for an IEEE robotics competition. The challenge involves navigating a 5x5 unknown grid maze containing 4 randomly placed colored cubes (2 blue, 2 red) and corresponding colored drop-off bins. The robot must autonomously scan the maze, identify objects, calculate optimal paths, and successfully transport each cube to its matching colored destination.

🤖 Challenge Overview

The IEEE logistics robotics competition presented a complex autonomous manipulation challenge:

- 5x5 grid maze with unknown layout and random object placement

- 4 colored cubes (2 blue, 2 red) positioned randomly throughout the maze

- Corresponding colored drop-off bins requiring precise color matching

- Fully autonomous operation - no human intervention allowed

- Time-critical performance evaluation

🧱 System Architecture

Our solution integrated advanced robotics hardware with intelligent algorithms for autonomous logistics operations:

Mobile Manipulator Platform

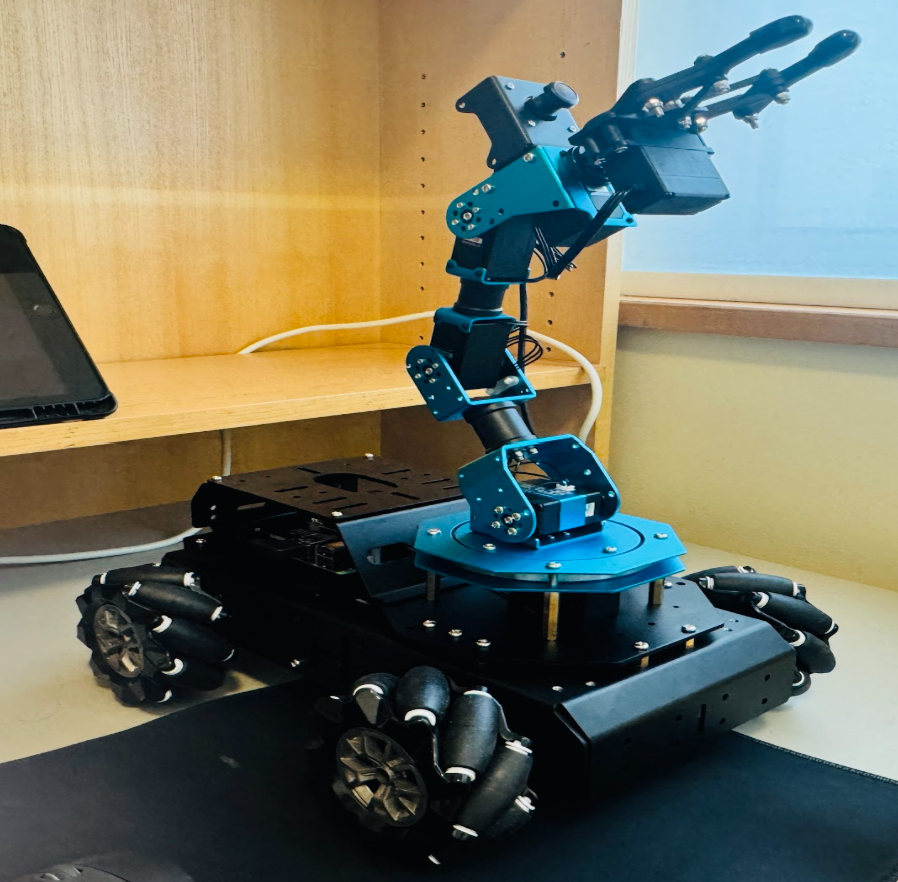

- Hiwonder Mobile Manipulator as the primary robotic platform

- Integrated mobility base with precision manipulator arm

- End-effector designed for reliable cube grasping and placement

- Sensor fusion for simultaneous navigation and manipulation

Computer Vision System

- Real-time object detection for colored cube identification

- Color classification algorithms for blue and red cube discrimination

- Drop-off bin detection and color matching verification

- Visual SLAM for maze mapping and localization

Path Planning & Navigation

- Dijkstra's algorithm for optimal path calculation

- Dynamic maze exploration and mapping

- Obstacle avoidance and collision detection

- Multi-objective optimization for efficient task sequencing

Hiwonder Mobile Manipulator autonomously navigating the 5x5 maze, identifying colored cubes, and executing optimal pickup and delivery tasks

🧠 Key Capabilities

Autonomous Maze Exploration

Dynamic scanning and mapping of the unknown 5x5 grid environment with real-time obstacle detection

Color-Based Object Detection

Computer vision system for accurate identification and classification of blue and red cubes

Optimal Path Planning

Dijkstra's algorithm implementation for shortest path calculation to minimize task completion time

Precision Manipulation

Accurate grasping, lifting, and placement of cubes using the integrated manipulator arm

Color Matching Logic

Intelligent algorithm ensuring each colored cube reaches its corresponding drop-off bin

Real-Time Execution

Time-optimized autonomous operation meeting competition performance requirements

🔧 Technical Challenges & Solutions

Unknown Environment Mapping

Implemented SLAM techniques for real-time maze exploration and dynamic map building without prior knowledge

Time Optimization

Developed efficient task sequencing algorithms to minimize total completion time in competitive environment

Precision Manipulation

Calibrated visual-servo control for accurate cube pickup and placement in confined maze spaces

🏆 Competition Results & Impact

This IEEE robotics competition project showcased advanced autonomous systems integration:

Competition Performance

Successfully demonstrated fully autonomous logistics operation in challenging unknown environment

Technical Innovation

Integrated computer vision, path planning, and manipulation in a cohesive autonomous system

Real-World Applications

Demonstrated technologies applicable to warehouse automation and logistics robotics

📈 Impact and Applications

This assistive technology project addresses critical mobility challenges for visually impaired individuals in urban environments:

Accessibility Innovation

Intuitive feedback system replacing complexity with meaningful, actionable guidance

Safety Enhancement

Real-time obstacle detection and traffic light recognition for safer navigation

User-Centered Design

Lightweight, comfortable, and intuitive design based on user feedback and testing

🧮 Algorithmic Approach

System Workflow

- Phase 1: Autonomous maze exploration and environmental mapping

- Phase 2: Object detection and color classification of cubes and bins

- Phase 3: Dijkstra's algorithm for optimal path calculation

- Phase 4: Sequential task execution with pickup and delivery operations

- Phase 5: Verification and completion confirmation

🔮 Future Applications

- 🏭 Automated warehouse management and inventory systems

- 🚛 Autonomous logistics and supply chain robotics

- 🏥 Hospital material transport and pharmaceutical logistics

- 🏪 Retail automation and smart inventory management

- � Laboratory sample handling and automated testing systems

- � Advanced multi-robot coordination for large-scale logistics

🎯 Project Reflection

The IEEE logistics robotics competition provided an excellent platform to integrate multiple robotics disciplines into a cohesive autonomous system. The project required seamless coordination between computer vision, path planning algorithms, and precision manipulation control.

Working with the Hiwonder Mobile Manipulator taught me the complexities of real-time autonomous decision-making in unknown environments. The implementation of Dijkstra's algorithm for optimal path planning, combined with dynamic object detection and color classification, demonstrated the power of intelligent systems in solving logistics challenges.

This competition experience highlighted the importance of robust system integration, efficient algorithm design, and the critical role of computer vision in modern robotics applications. The project serves as a foundation for understanding autonomous logistics systems that are increasingly vital in industrial automation and smart manufacturing environments.