Unitree Z1 Robotic Arm: Wine Pouring Task

Abstract

This project showcases the Unitree Z1 6 DOF robotic arm performing the task of pouring wine into a glass. The robot utilizes a full pose impedance controller, enabling compliant and precise manipulation of the bottle to achieve smooth pouring. The controller manages both position and orientation, allowing the arm to adapt to contact forces and ensure safe, accurate execution of the task.

Methodology

The project leverages advanced robotics control and simulation techniques:

Robot Control Implementation

- Full pose impedance control for compliant and safe manipulation

- 6 DOF control of the Unitree Z1 robotic arm

- Real-time force and torque feedback for adaptive pouring

- Trajectory planning for bottle grasping, lifting, and pouring

Simulation & Experimentation

- Physics-based MuJoCo simulation for controller validation

- Integration with Unitree Z1 hardware and sdk

This GIF shows the planned replication of the wine pouring task as presented by Unitree on their official website.

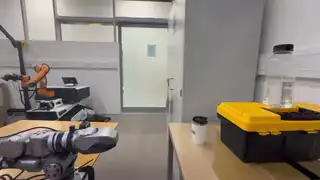

Demonstrates the robot grasping a bottle placed at Location A. Overhead camera view used for visual servoing and localizing the bottle relative to the gripper during approach and lift.

Shows the robot grasping a bottle presented at an angled orientation. Highlights the gripper approach and wrist accommodation for secure, adaptive grasping of a tilted object prior to lifting and pouring.

Shows the robot performing a grasp on the bottle positioned at Location B. Calibration and alignment between camera and wrist frame ensure a robust closed-loop grasping behavior.

Example of the robot selecting and executing a grasp for a bottle at Location C. Predicted grasp proposals are overlaid to illustrate candidate poses and the chosen secure, ergonomic grasp used before pouring.

The robot demonstrates compliant pouring, adapting to contact forces and glass position.

Key Innovations

Full Pose Impedance Control

Enables compliant, safe, and precise manipulation of the bottle for pouring tasks.

6 DOF Robotic Arm

Utilizes the Unitree Z1's full range of motion for complex manipulation.

Adaptive Task Execution

Real-time feedback and control for robust pouring, even with environmental uncertainties.

Impact and Future Directions

This project demonstrates advanced compliant control and manipulation capabilities with the Unitree Z1 robotic arm, paving the way for safe human-robot interaction and automation in service robotics:

Educational Value

Illustrates modern impedance control and its application in real-world tasks.

Technical Innovation

Demonstrates full pose impedance control for safe, adaptive manipulation.

Service Robotics Applications

Potential for automation in hospitality, healthcare, and domestic environments.

Future Enhancements

- Integration of visual feedback for glass localization

- Extension to multi-object manipulation and serving tasks

- Deployment on real Unitree Z1 hardware for field testing

- Exploration of learning-based approaches for improved adaptability

- Collaborative tasks with multiple robots

Conclusion

The Unitree Z1 robotic arm wine pouring project demonstrates the effectiveness of full pose impedance control for compliant, precise, and safe manipulation. The robot successfully adapts to contact forces and environmental uncertainties, making it suitable for service robotics and automation tasks requiring delicate handling.